What is a Flexible Connector?

A rubber flexible connector pump flexible, which can often be referred to as a rubber expansion joint or flexible coupling, is an essential component in various piping and plant room systems. These rubber flexible connector pump flexibles are designed to absorb vibrations particularly from main plant room pumps for water and they also reduce noise in mechanical systems. Their flexibility allows them to effectively manage the movement of the vibration and our ELAFLEX ROTEX Rubber Expansion Joint range allow any misalignment of pipes and ducts, making them crucial in applications across multiple industries, including HVAC, plumbing, and industrial manufacturing.

One of the key features of rubber flexible connector pump flexibles is their ability to handle different types of movements. They can accommodate flexibility which helps prevent stress on the piping system, reducing the risk of leaks or damage over time which also protects the very often expensive pumping equipment

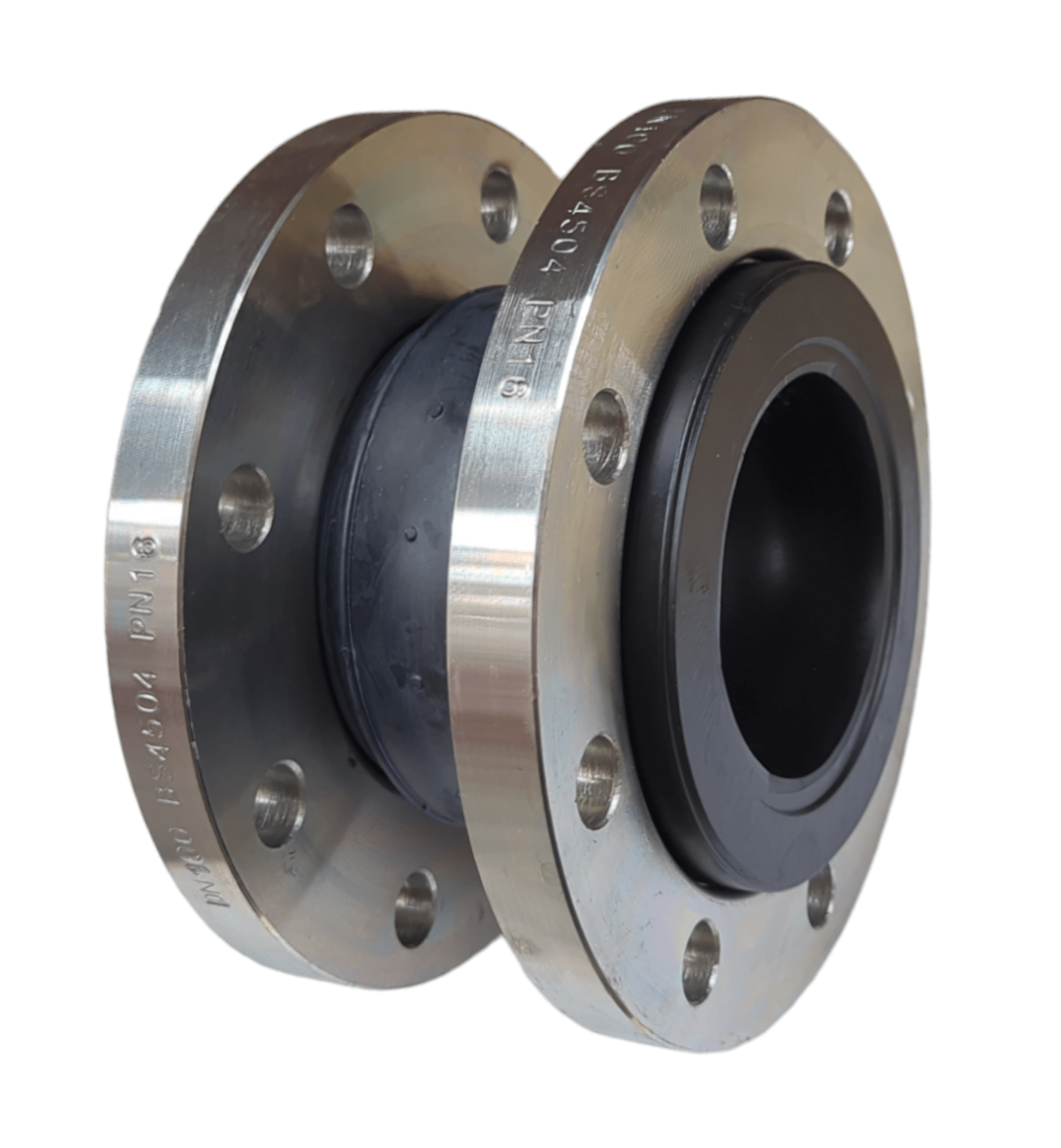

The construction of a rubber flexible connector pump flexible typically involves layers of rubber and fabric, which provide strength and durability. The rubber is often compounded with additives to enhance its resistance to heat, ensuring that the connector can withstand harsh operating conditions. Our rubber flexible is made from EPDM (ethylene propylene diene monomer) rubber, which offers unique properties suitable for the application.

In HVAC systems, rubber flexible connector pump flexibles are widely used to connect to pumps, chillers, and other equipment. They help isolate vibrations generated by these machines, preventing them from being transmitted through the pipework, which can lead to noise and discomfort in occupied spaces. By using rubber flexible connector pump flexibles, HVAC systems can operate more quietly and efficiently, improving overall comfort and energy efficiency.

In plumbing applications, these rubber connectors play a vital role in managing the movement of pipes due to the vibration they’re subjected too. If the pipework is rigidly connected, this can lead to stress and potential failure. Rubber flexible connector pump flexibles allow for this movement, ensuring that the plumbing system remains intact and functional over time.

Another significant advantage of rubber flexible connector pump flexibles is their ease of installation. They can be quickly and easily installed in existing systems without the need for extensive modifications. This makes them a popular choice for retrofitting projects or when upgrading existing systems. Additionally, their lightweight design simplifies handling and installation, reducing labour costs and time.

It's also important to consider the maintenance of rubber flexible connector pump flexibles. While they are generally low-maintenance, regular inspections should be conducted to check for signs of wear, cracking, or degradation. Environmental factors such as exposure to sunlight, chemicals, and extreme temperatures can affect the lifespan of the rubber, so monitoring these conditions is essential for ensuring long-term performance.

In summary, rubber flexible connector pump flexibles are critical components in various piping and ducting systems, providing vibration absorption, and noise reduction. Their durable construction and ability to accommodate different types of movements make them ideal for use in HVAC, plumbing, and industrial applications. With their ease of installation and low maintenance requirements, rubber flexible connector pump flexibles contribute to the efficiency and reliability of mechanical systems, ensuring they operate smoothly and effectively over time.

Specification

Temperature limits: -10 – 90˚C

Installed length: - 130mm

Suitable for 6 bar working pressure

Flanges BZP coated carbon steel PN16

Key Points

Flanges: Carbon Steel - Drilled PN16 or PN6

Nylon Re-enforced EPDM Rubber Body

Steel Reinforced Collars

Round Flanges - No Tie Bars

Our units have up to 10 year design life* and are warranted for a period of 12 months** from supply.

Our units are stamped with Origin of Manufacture, Date of Manufacture, Batch Number and Size.

Please note no torsion forces should be applied to these units.

* Design life is guidance only. This guidance assumes the unit will not be working at the extremes of its working capacity. This is no way implies a warranty or a guarantee.

** 12 Months Warranty is against manufacturing defect only and is limited to the supply only of a replacement product of the same type.

Additional information

| Size (mm) | 32, 40, 50, 65, 80, 100, 125, 150 |

|---|---|

| Bar | PN6, PN16 |